There are many effects and sources of residual stress in steels. Tensile surface residual stresses are detrimental and may cause cracking during fabrication or reduced resistance to fracture in service, whereas surface compressive stresses are generally beneficial and prevent cracking during manufacture and service. Short of cracking, residual stresses may cause distortion and undesired dimensional changes. A major source of residual stresses during heat treatment is expansion or contraction of surface microstructures at different times than interior microstructures because of differences in surface and interior cooling or heating rates. Control of residual stresses during the various stages of hardening is a major consideration in all phases of the heat treatment of tool steels. In tool steels, residual stress-relief treatments are most commonly performed following machining and grinding operations to shape a finished tool. These operations may introduce plastic deformation and high surface strains, typically in annealed, machinable ferrite-carbide microstructures, which on subsequent hardening may cause distortion and cracking. Grinding operations applied to hardened tools with tempered martensitic microstructures, or to tools that have been work hardened in service, may also cause cracking and high residual stresses before or during service .To maintain hardness, stress-relief treatments on reground tool steels should be performed at temperatures at or below the tempering temperatures used to produce the required hardness of the tool.

stress-relief heat treatments are generally of short duration (1 to 2 h) or, in larger sections, 1 h/25 mm (1 in.) of section thickness.

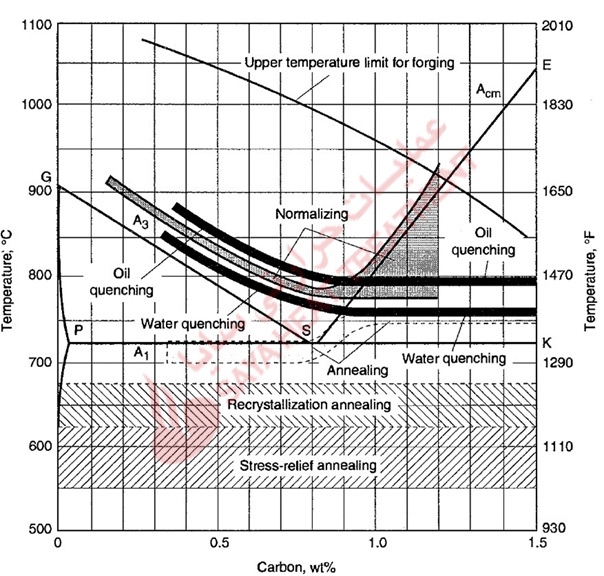

The temperatures for stress-relief heat treatments are typically between 550 and 650 °C (1020 and 1200 °F) for plain carbon and low-alloy steels and between 600 and 750 °C (1110 and 1380 °F) for hot-work and high-speed steels. As noted earlier, stress relief is also a function of time at temperature, but generally temperature has a much stronger effect on the kinetics of stress relief than does time. Heavy sections should be cooled very slowly from stress-relief temperatures.

to at least 300 °C (570 °F) (Ref 4) and then air cooled. Otherwise, distortion and new residual stresses may be introduced due to uneven cooling of surfaces and interiors,