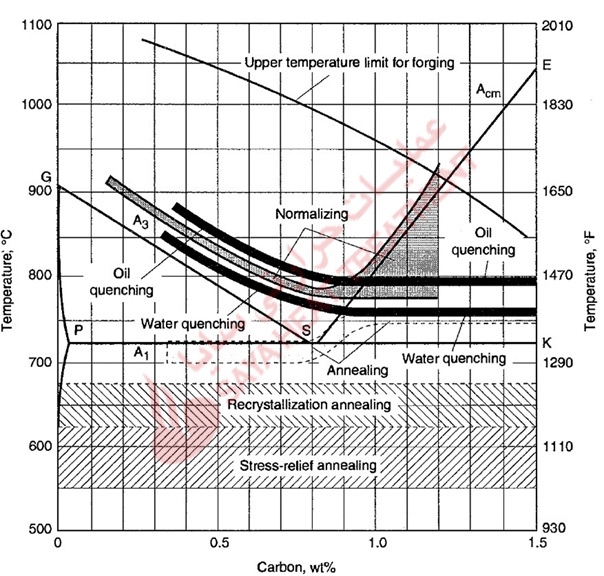

This heat treatment is applied to tool steels that have been forged at high temperatures, as shown in Fig. 5-3. Forging deformation, depending on part geometry, may cause localized variations in microstructure and, because of the high temperatures used, may produce a coarse, austenitic grain structure. Normalizing is performed to produce more uniform, fine-grained microstructures for subsequent annealing and hardening heat treatments. Also, in tool steels with high stable carbide contents, the carbides may be preferentially aligned in the direction of hot work, and normalizing will help to produce more uniform distributions.

The cross-hatched temperature region shown in Fig. 5-3, then air cooling. As shown, the normalizing temperatures for hypereutectoid steels approach and sometimes exceed Acm temperatures. Therefore, during heating to and holding at the normalizing temperature, austenite grains nucleate and grow from the ferrite-carbide microstructures stable at low temperatures. Considerable carbide dissolution, depending on alloy content, takes place during heating. During cooling, austenite then transforms to mixtures of ferrite and cementite. If the alloy content of a tool steel is low, cementite and pearlitic microstructures will form during air cooling, and the carbides in these structures will be spheroidized in subsequent annealing treatments. In hypereutectoid steels, where the microstructure is completely converted to austenite during normalizing, cementite networks will form on austenite grain boundaries on cooling prior to pearlite formation.

In tool steels with high alloy content, high hardenability may cause martensite to form during air cooling. Hardenability is the topic which relates alloying to the phase transformations that occur on cooling . Although air hardening in tool steels with high hardenability is a beneficial characteristic during final hardening, martensite formation combined with the high austenitizing temperatures of normalizing may cause cracking, especially if carbide networks that provide pathways for brittle fracture are present. Therefore, air-hardening tool steels usually are not normalized.